Life Cycle Assessment (LCA): Why a customized approach is crucial for companies

- Lina Kindermann

- May 12, 2025

- 7 min read

You've almost completed your extensive reporting requirements – collecting company data, creating carbon footprints, and writing environmental reports. But now the real question arises: How can you truly make your products more sustainable? Where do you start to not only meet legal requirements but also create added value with innovative, sustainable products and services?

Or perhaps you're already one step ahead: Your company is investing in sustainable materials, optimizing production processes, and improving recycling strategies. But are you allocating your resources where they will have the greatest impact - or are you at risk of getting lost in inefficient individual measures?

This is where life cycle assessment (LCA) comes in. It provides precise information about where a product's greatest environmental impacts occur – and where optimization really counts.

Why is a life cycle assessment so valuable?

It identifies the greatest levers for sustainable product improvements

It makes environmental impacts visible along the entire value chain

It helps to use budget and resources specifically where they have the greatest impact

Only those who understand exactly how a product behaves throughout its entire life cycle can make well-founded decisions – and not only measure sustainability but also actively manage it.

What is life cycle assessment?

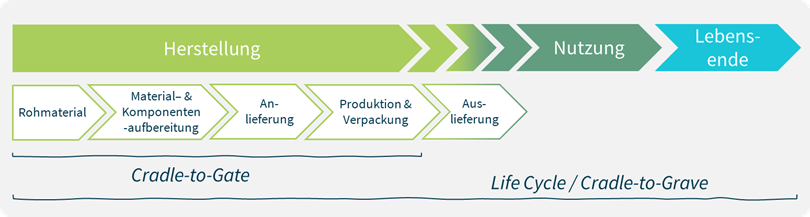

A life cycle assessment (LCA) is a scientifically sound method for analyzing the environmental impacts of a product, process, or service throughout its entire life cycle, i.e., "cradle to grave" – from raw material extraction to disposal or recycling. It is based on internationally recognized standards such as ISO 14040 and ISO 14044 and serves as a foundation for sustainable product design, environmental communication, and strategic decisions.

Where can an LCA be applied?

The results of a life cycle assessment can be used in a variety of ways, for example for:

These valuable insights make it possible to communicate environmental impacts to customers, improve products, develop data-driven sustainability strategies, and much more. Transparency of hotspots allows resources to be targeted where they will have the greatest impact.

PCF, LCA and EPD - which of these do I need?

Various terms are often used in connection with environmental assessments. Here is an overview:

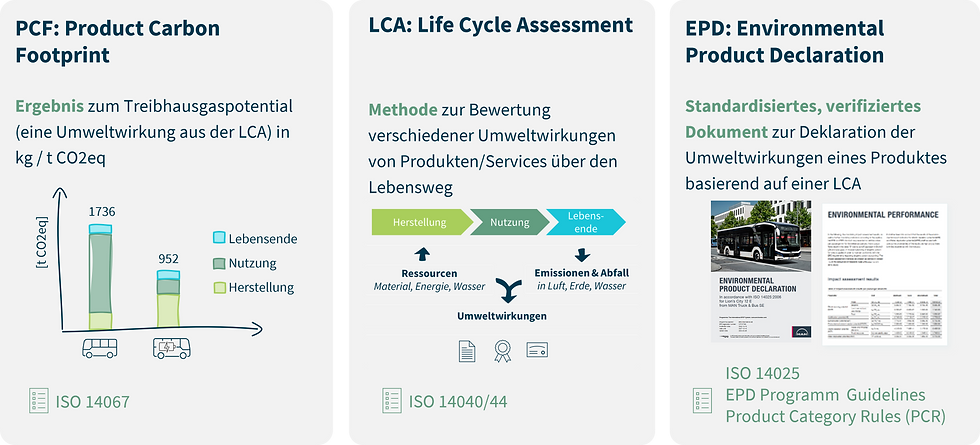

Life Cycle Assessment (LCA): A comprehensive method for analyzing the environmental impacts of a product, process, or service throughout its entire life cycle—from raw material extraction to disposal or recycling. The LCA yields various environmental indicators such as climate change potential/carbon footprint, acidification potential, ozone depletion potential, and more. The method thus allows a holistic approach to avoid burden shifting —for example, improvements in one environmental category at the expense of others, or reductions in the production of a product that result in higher environmental impacts in other life cycle phases.

Product Carbon Footprint (PCF): One sub-result of the LCA is a product's carbon footprint. This is the key metric for climate/decarbonization strategies to reduce the climate impact of products. It is often requested by customers as a basis for their reporting and CO2 management along the value chain.

Environmental Product Declarations (EPDs): Standardized environmental product declarations based on LCA data. They enable transparent communication about a product's environmental impacts using standardized formats. Product Category Rules (PCRs) are relevant for the preparation of the LCA and the declaration. These PCRs set requirements for the implementation of the underlying LCA and the reporting format. This type is common in some industries (e.g., construction and packaging).

While a PCF often serves as an entry point and an EPD is a standardized reporting format, LCA remains the comprehensive and fundamental method for analyzing and optimizing products.

💡 Practical tips:

Clear needs analysis : Take the time, especially at the beginning, to clarify the requirements for your analyses. Gain clarity about regulatory requirements (CSRD, ESPR, Green Claims, CBAM, etc.) and the necessary results, the needs of customers and marketing, and other relevant stakeholders. Clarity in the objective is the basic prerequisite for setting up the analysis correctly and avoiding subsequent, expensive and time-consuming changes.

Manual vs. Automated: Which approach should I choose?

Companies are faced with the choice between two basic methods for life cycle assessment:

1. Manual analyses: Detailed but time-consuming

Traditional LCAs are often conducted by specialized sustainability teams or external consultants. They offer a high level of detail and enable customized analysis, but are time-consuming, costly, and difficult to scale.

Advantages:

High accuracy and adaptation to company-specific processes

Suitable for one-off, in-depth analyses or product innovations

Disadvantages:

High time expenditure

Internal expertise required or external costly implementation

Limited scalability, especially for large product portfolios

2. Automated analyses: Fast and scalable

Thanks to digital tools and data platforms, LCAs can now be increasingly automated. Software solutions draw on extensive databases to efficiently calculate and regularly update environmental impact assessments.

Advantages:

Faster calculations and continuous updates

Scalable for larger product portfolios

Reduced manual effort

Disadvantages:

The basic requirement is the availability of consistent and qualitatively sufficient product data – often this is not available from the outset, but has to be built up manually

Less flexibility and individual customization options

Dependence on available databases and their accuracy

The choice between manual or automated LCA depends on the company's requirements and data availability. While manual LCAs are useful for strategic individual analyses and consistent product portfolios, automation offers clear advantages for companies with a large number of different products and a need for continuous evaluation.

I'm just starting out and would like to manually analyze my first products: How do I proceed?

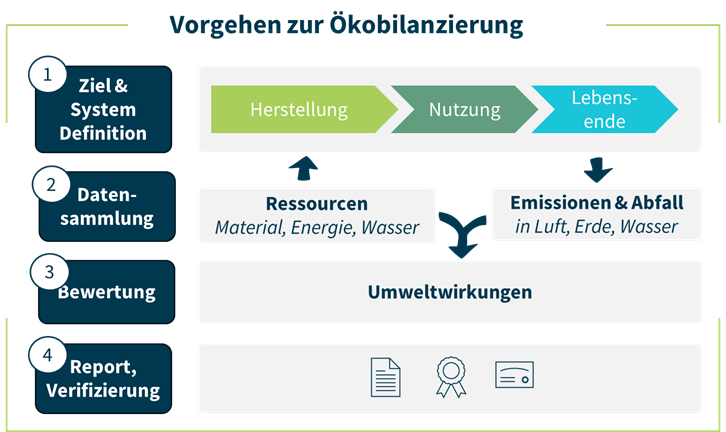

A manual LCA follows a structured approach to ensure reliable results. The steps can be performed iteratively:

Objective and system definition : This defines the purpose for which the LCA is being created, which processes are being considered, and, for example, what the product's function is. Depending on the product, different environmental impacts and KPIs may be relevant; in this step, it should be defined which outcomes are being considered. In addition to the carbon footprint, land-use change, eutrophication, and water footprint may be relevant for bio-based materials, for example. For energy-intensive products, it makes sense to include primary energy consumption and acidification potential.

Data collection : All data required for the goal and the system are collected – on product composition, production, supply chain, logistics, use, and end-of-life. Relevant quantities of input resources and output, emissions, and waste are recorded.

💡 Practical tips:

Gradual detailing : Start collecting data with coarse data and increase the detail for aspects that cause major environmental impacts. Models should be only as detailed as necessary to derive insightful results for optimizing hotspots—for example, for estimating material emissions at the level of purchased subcomponents or assembling in-house components into material groups to optimize material usage.

Automation : Manual collection and processing is possible for individual products, but it is quite time-consuming and not sustainable for a broad product portfolio. An efficient and, if possible, automated approach to data collection and processing is therefore a key factor for later scaling of analyses. Therefore, focus on improving the quality of master data and thus enabling long-term automation.

Modeling and environmental assessment: The data is incorporated into models using specialized life cycle assessment software (e.g., Spera LCA for Experts, openLCA, or SimaPro), and environmental impacts are calculated. During modeling, the resource and energy inputs required during the life cycle, as well as the resulting emissions, are linked to datasets from stored databases. These contain information on the resulting environmental impacts for the respective material and energy flows. After successful modeling, the desired calculation models for the environmental impact categories can be selected, and results can be generated.

These results can be used to identify key "hotspots," i.e., areas with the highest environmental impacts. Additional KPIs for increasing product circularity, such as recyclability or repairability, may need to be calculated separately, as not all of them can be mapped using life cycle assessment software.

💡 Practical tips:

Translation mechanisms: Mapping collected data to database records can be very time-consuming. It is helpful to develop translation mechanisms so that materials/components/energy flows/emissions, etc., are modeled consistently. Import functions for product bill-of-materials (BOMs) can help with this.

Keep it simple : Try to keep the models as simple as possible in the first step, adding detail where necessary to achieve the goal. Parameterized models can help facilitate scenario analyses and subsequent adjustments to the models – a good description and documentation of the parameters to be entered is useful for easy traceability.

Report & Verification : If necessary, the procedure and results can be summarized in a report at the end and verified by an independent third party.

💡 Practical tips:

Auditor Exchange: The choice of verifier can have a significant impact on the depth and approach of the audit—everyone audits differently. Especially when developing new approaches, parallel reviews during the LCA development process can help review the approach step by step and make adjustments along the way. Early communication with verifiers can thus help protect against unpleasant verification surprises.

The results then serve as a scientifically sound basis for sustainable decisions!

The key: A tailored LCA approach for your company

There's no one-size-fits-all approach—every company requires a unique approach. Which questions are critical for your company?

✔ What should the results of the analysis be used for and what requirements arise from them?

✔ Is a one-time analysis required or do regular evaluations make sense?

✔ Is the focus on CO₂ emissions or a holistic environmental balance?

✔ Should the analysis be carried out internally or is external expertise required?

Conclusion: Individually tailored life cycle assessment approaches are an indispensable tool for sustainable companies

Whether manual or automated, whether PCF, LCA, or EPD – sound analysis is essential for modern companies. A tailored approach ensures that sustainability measures not only appear convincing but also have a lasting impact. Companies that strategically use life cycle assessments can not only reduce their environmental impacts but also secure competitive advantages, reduce costs, and minimize regulatory risks. The key is to find the right balance between accuracy, scalability, and effort.

Do you need proven expertise to find the right approach for your company? Contact me now! Together we'll find solutions for your needs!

I support you in identifying requirements, selecting suitable approaches and software, and in the step-by-step implementation in your company.

Comments